It is not surprising that automation has emerged as one of the foremost factors pointing towards changes in processes of modern machine tools. Indeed, there are astounding benefits in terms of efficiency, accuracy, and cost effectiveness. As the development of industries continues to expand, the establishment of automation, movement engineering, usage of computer systems (CNC) and artificial intelligence has altered the perspective of production completely. This paper outlines the effects of automation of machine tools in Machining modern practice focusing on the merits and demerits and the possible further advancements.

1. Improved Level of Quality and Precision

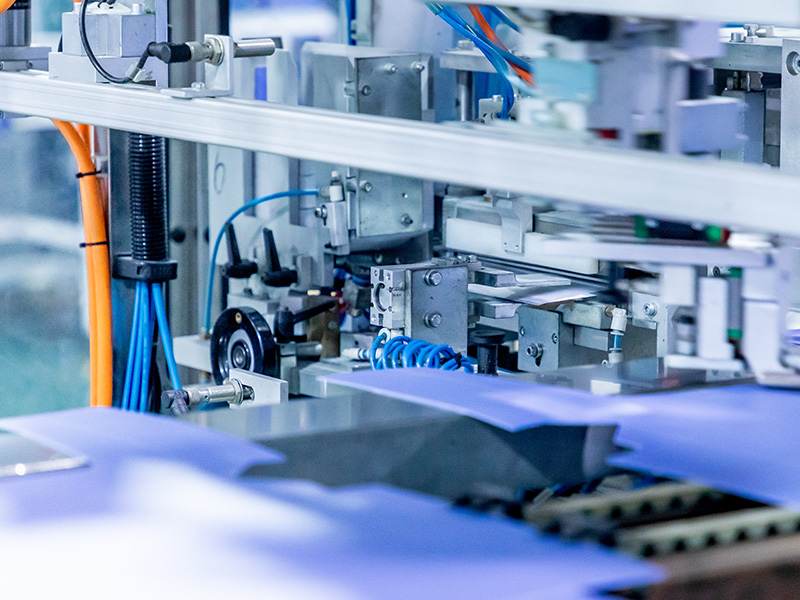

Precision automation tooling technologies remain a great advancement in the machining process due to the presence of CNC Machines. All that is required from these machines is to program them with the task at hand, and it is expected that the work is done that way with no possibility of making mistakes. cnc systems are capable of working with forms and others designs that no other form of machine planting could do successfully. The reduction in number of mistakes caused by human beings through the employment of automated processes increases the quality of end products which are required for high end industries such as manufacture of parts for aeroplane and cars.

2. Efficacy and Productivity enhancements.

Raising efficiency and increasing productivity is something most automation in machining has been designed to have the most effects. Human labor cannot be compared with machines as the automated systems are able to operate day and night without requiring any break. This allows a company to have production lines that run the whole day and thus raises production significantly. Furthermore, these kinds of processes help in decreasing cycle time as machines can perform many tasks more efficiently compared to human hands thereby improving the time taken to produce goods and also deliver them in the market.

3. Cutting the cost down.

A common barrier however that most companies have especially during their initial stages is the high investment cost that comes with adopting automation technology However, savings in cost are realized in the long run. Fewer operating personnel are required in the machining processes that have now automated, hence low labor costs. More so, materials wastage is brought down through automation due to how accurate the processes become with less or no faults. These and more factors further lead to reduced operating expenses over the years and therefore making the use of automation a cheaper option for the manufacturers.

4. Enhanced Security

Most of the processes performed during machining require the use of tools and heavy machines, which expose human operators to safety hazards. To improve safety within the workplace, there is a reduced need for people to work in dangerous situations. Dangers can be mastered by utilizing robots or CNC machines, while people can control such processes from a non-hazardous zone. This change has brought a notable improvement in terms of work injury cases in automated industries.

5. Expansion and Flexibility

It is true that nowadays automatic machining systems even more customized in terms of flexibility design. For example, CNC machine tools can be used for a small quantity production as well as for mass production, because it is possible to make quick reprogramming. Furthermore, it helps to adjust those manufacturing operations in the period of increasing or lowering the market demand with no clearly defined borders of extensive training or altering the usual manual processes.

6. Challenges of Automation in Machining Processes

Automation in machining is often accompanied by several problems. Firstly, the cost incurred in automation technologies such as robots, CNC machines as well as AI-based systems needs an active investment which may not be affordable to small manufacturers. Second, and very importantly, automation also requires skilled operators and technicians to run and take care of the systems, creating a make-or-break skills gap in the workforce. Finally, there is the problem of rapid technological development, whereby there is a need to keep on purchasing new upgrades to enhance the systems in order to keep up with the competition.

7. The Prospects of Automation in Machining Specifically in Relation to Its Theory of Impact on Cncs and Robotics

As for the automation of machining processes in the future, one can hope that it will be further improved due to the evolution of AI and machine learning enhancing the functions of CNC systems and robots. Due to the evolution of AI, systems will operate with the capability of optimizing themselves without any human input by improving on the efficiency of working with real time system based data. Moreover, advanced IIoT which connects machines will bring in even more opportunities for interconnectedness of the machines for better and quicker manufacturing processes.

There is little doubt in saying that automation has influenced the changes that have taken place in the machining methods used today. In the case of realized automation, there will always be some limitations, especially on costs and skill requirements on the available workforce. Automation is the key for the companies to compete within the preferred and to forma figure and everything outside that figure is superfluous. It is only inevitable that with time, automation will come to dominate manufacturing processes especially due to the pressures of competition.